Robotics

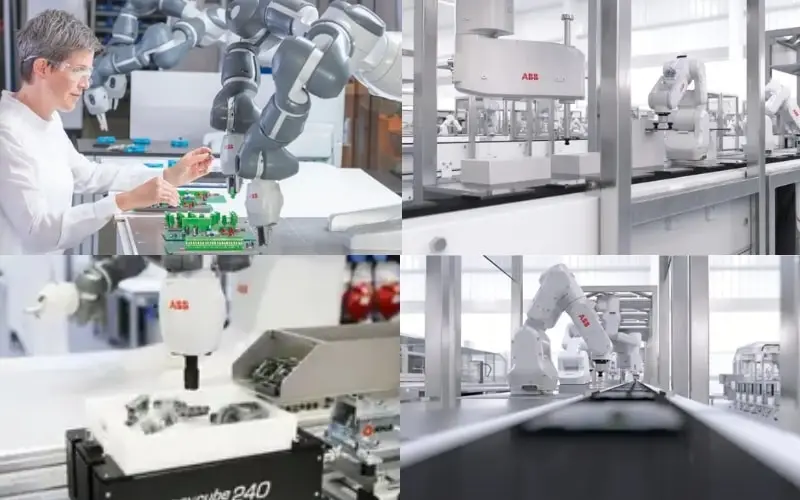

ABB ROBOTICS – A PIONEER IN INDUSTRIAL ROBOTICS

ABB Robotics is one of the world’s leading providers of industrial robots, pioneering the development and application of robotics across various industries. With over 40 years of experience, ABB has delivered over 500.000 robots to customers globally, enhancing production efficiency, product quality and worker safety.

Classification of Robotics

Different types of robots have specific design criteria and applications for various industries. ABB classifies robotics into the following types:

Articulated Robots: Created with TrueMove and QuickMove motion control technology, these robots feature articulated joints that enhance productivity and quality.

Collaborative Robots: Designed for multi-tasking, these robots are easy to install, program, operate and expand, making them suitable for all operational scales.

Paint Robots: Engineered to boost productivity and quality in painting operations.

Delta Robots: Leading in high-speed packaging and sorting technology, these compact robots provide high flexibility.

SCARA Robots: Offering fast cycle times, high accuracy and reliability for material handling, loading & unloading, pick & place, assembly & inspection of small parts.

Palletizer Robots: Designed to shorten cycle times and increase productivity for end-of-line palletizing applications, with multiple input/output and bag handling capabilities.

Advantages of Robotics

ABB Robotics stands out as a top choice in industrial automation, featuring several key advantages:

High productivity and quality: Achieves precision up to 0.6 mm even with multiple robots operating at speeds of up to 1600 mm/s.

Unprecedented scalability: OmniCore provides the largest control platform on the market, with 5 different controllers operating on the same platform.

Sustainability commitment: Integrates energy regeneration technology into the power grid, saving up to 20% energy compared to previous generations.

Easy integration: Supports all major communication protocols within a single control platform.

Comprehensive cybersecurity and traceability: Integrated network security and traceability features enhance quality and productivity by minimizing downtime.

Safety: Complies with future safety standards with 100 safety configurations to meet various use case needs.

Future-Proof design: Easily integrates cutting-edge computing power, supporting AI, cloud and advanced imaging systems.

Applications of Robotics in practice

ABB Robotics is utilized in a wide range of fields such as automotive, metal processing, casting, electronics, machine tools, and pharmaceuticals. Each industry has specific design criteria and solutions tailored to enhance productivity and product quality.

Automotive industry: Improves accuracy in assembly, reduces production time, and ensures product quality. Additionally, it is used for painting and quality inspection to optimize production efficiency.

Metal processing: Supports processes such as cutting, grinding, welding, and polishing.

Casting and molding: Enhances precision in casting products and reduces material waste.

Electronics: Performs tasks such as soldering circuit boards, assembling boards, and inspecting products with high speed and absolute precision.

Pharmaceutical industry: Handles tasks like packaging, quality inspection, and material management in sterile environments to enhance safety and product quality.

No products were found matching your selection.