As engineers face increasing demands to optimize output from existing facilities, Coriolis flow meters have become increasingly popular. This proprietary measurement technology allows direct mass and density measurement with high accuracy, without requiring additional sensors to derive mass flow. Let’s explore an overview of this device through the following article.

Understanding Coriolis Flow Meters

Coriolis flow measurement is a precise method for measuring the flow of liquids and gases. Coriolis flow meters operate based on the principle of the Coriolis effect, in which the rotational movements of liquid or gas create a force acting on the measuring tubes, thereby determining the flow rate of the liquid or gas.

Basic Structure and Operating Principles of Coriolis Flow Meters

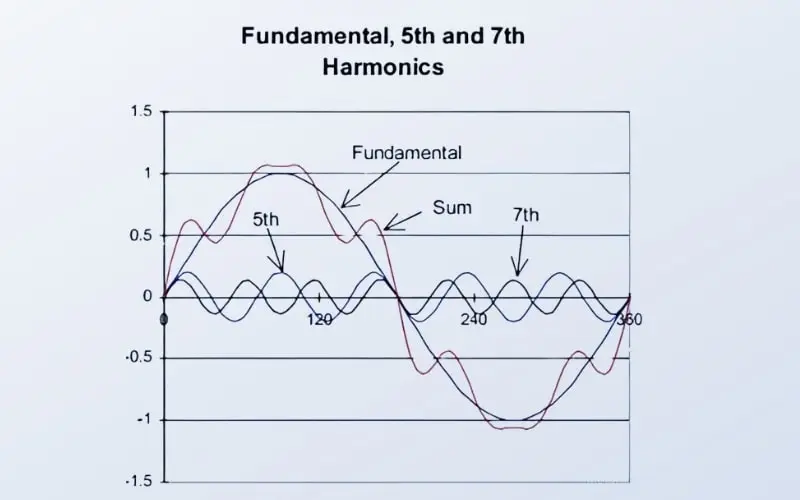

- Basic Structure: Includes single-tube, dual-tube, or quad-tube designs. These tubes typically vibrate when fluid passes through at a frequency determined by a driver.

- Coriolis Effect: When liquid or gas flows through the vibrating tubes, it creates a Coriolis force due to the interaction between the fluid movement and the vibrational movement of the tube. This force deforms the tubes in a specific way.

- Deformation Detection: Depending on the flow rate and mass of the liquid or gas, different deformations are produced. Through this analysis, the mass flow rate of the liquid or gas flowing through the tube can be calculated.

- Direct Mass Flow Measurement: Unlike other flow measurement methods, Coriolis flow measurement directly measures mass flow rather than volumetric flow.

KROHNE’s Coriolis Flow Meter Products

KROHNE manufactures diverse models suitable for various usage needs. You can refer to some of the following prominent Coriolis flow measurement products:

- OPTIMASS 1010/1400 Series: Handles high-viscosity liquids, liquids containing suspended solids, and gases. Achieves good performance in applications requiring high accuracy and reliability.

- OPTIMASS 3010/3400 Series: Designed to handle complex industrial applications requiring high accuracy. Features automatic compensation for temperature and pressure fluctuations, ensuring consistently accurate measurement results.

- OPTIMASS 7010/7400 Series: With diverse measurement capabilities and modern integrated features, the OPTIMASS 7400 is an ideal choice for flow and density measurement solutions in industrial environments.

- OPTIMASS 2400 Series: Used for handling large flow rates and harsh operating conditions. Flow tubes are made from materials such as stainless steel, Hastelloy, titanium, and other alloys, suitable for applications requiring corrosion resistance and high durability.

- OPTIMASS 6400 Series: Designed to handle complex industrial applications requiring high accuracy. With high precision, diverse measurement capabilities, and high integration features, this device is a top choice for flow and density measurement solutions in industrial environments.

Advantages of KROHNE’s Coriolis Flow Meters

- High Accuracy: Measurements accurate to ±0.1% or even ±0.05% for mass flow.

- Direct Mass Flow Measurement

- No Moving Parts: Minimizes wear and maintenance costs while increasing reliability and device lifespan.

- High Flexibility

- Easy Integration into Control Systems: The device supports many communication protocols such as HART, PROFIBUS, FOUNDATION Fieldbus, Modbus, EtherNet/IP.

- Durable and Corrosion-Resistant Design: Made from high-quality materials such as stainless steel, Hastelloy, and titanium, ensuring durability and corrosion resistance in harsh environments.

Industrial Applications

With the Coriolis flow measurement method, KROHNE offers diverse device types to suit various needs in most industries: requirements for size, installation location, accuracy, fluid viscosity, etc.

- Chemical and Processing Industry: Concentration and density measurement, mixing and blending into reactors

- Oil and Gas Industry: Custody transfer (financial measurement) for crude oil and other hydrocarbons, pipeline measurement, odorization of natural gas and propane, online density and concentration measurement

- Pharmaceutical Industry: Solvent extraction, packaging, and dosing

- Food and Beverage Industry: Packaging, dosing and filling, concentration measurement

- Marine Industry: Fuel level measurement

- Pulp and Paper Industry: Additives, bleaches, and colorants

- Water and Wastewater Industry: Coagulant dosing, flow and sludge density measurement

Through this article, TESFA aims to provide readers with the most comprehensive overview of KROHNE’s CORIOLIS flow measurement devices (Coriolis Flowmeters), as well as highlight the importance and widespread application of these devices in most industries today.

TESFA Co., Ltd. is honored to be one of KROHNE’s leading authorized agents – pleased to support and accompany you!