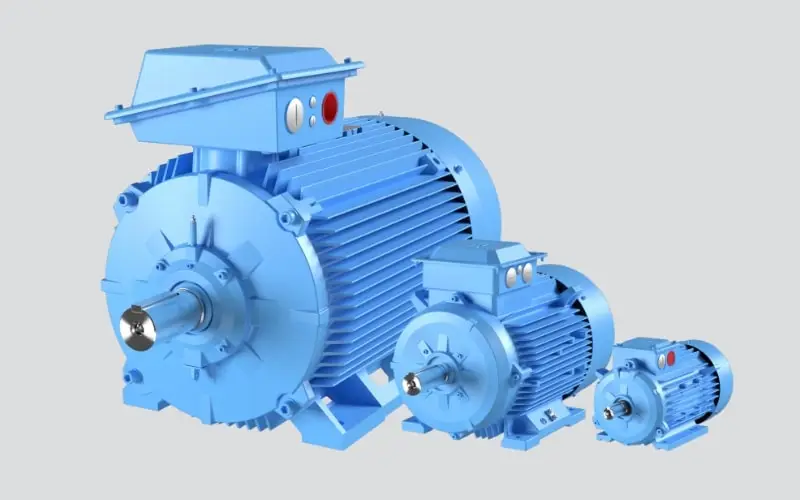

Industrial motors are essential devices in the electro-mechanical systems of many industries. These devices play a crucial role in providing energy to control machinery and equipment, helping production processes run continuously and efficiently. Let’s take a closer look at industrial motors and the presence of some world-famous manufacturers through this article.

What are Industrial Motors?

Industrial motors are mechanical devices used to convert electrical or mechanical energy into mechanical motion. They are specially designed to operate durably and efficiently in harsh industrial environments that require high performance. In industrial settings, they are commonly used in machinery such as compressors, pumps, fans, and other mechanical equipment.

Motors are widely applied in various fields including: manufacturing and processing, automation systems, water and waste treatment, mining industry, and more.

Structure of Industrial Motors

Industrial motors typically have a structure consisting of the following main components:

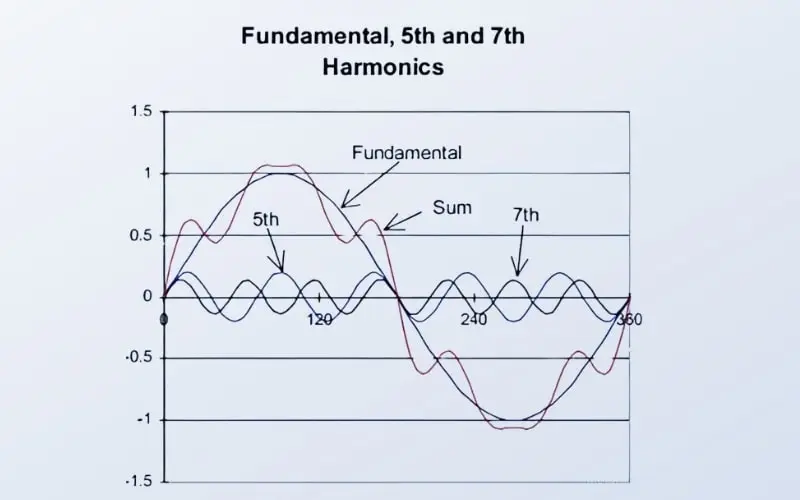

- Stator: The stationary part containing magnetic coils that create a magnetic field when current flows through.

- Rotor: The moving part of the motor, rotating inside the stator under the influence of the magnetic field. The rotor is usually made of thin steel sheets laminated together to reduce magnetic losses.

- Windings: The coils in the stator and rotor help create the necessary magnetic field for the motor to operate.

- Commutator: The switching component that helps change the direction of current in the rotor windings, adjusting the magnetic field for continuous rotation.

- Motor Shaft: The shaft connects the rotor with peripheral mechanical devices. It transmits motion from the motor to other devices through drive mechanisms such as gears, belts, or screws.

- Bearings: Support smooth rotation of the rotor and reduce friction in the motor.

- Motor Housing: Protects the internal components of the motor and provides mechanical connections to other systems.

Classification of Industrial Motors

Industrial motors can be classified based on various criteria, including:

Based on Energy Source

- Electric Motors: Use electrical energy to create mechanical motion.

- Diesel Motors: Use diesel fuel, common in heavy applications and harsh environments.

- Pneumatic Motors: Use compressed air to generate motor force.

Based on Construction

- AC (Alternating Current) Motors: Operate with alternating current, common in standard industrial applications.

- DC (Direct Current) Motors: Operate with direct current, providing easy speed adjustment.

row ]

Based on Type of Motion

- Induction Motors: Do not require brushes and commutators, suitable for many industrial applications.

- Synchronous Motors: Ensure precise rotation speed with the frequency of the power source.

Role of Motors in Industry

From light to heavy industries, motors play a key role in equipment and machinery. Let’s review some of these roles:

- Providing Motion: Industrial electric motors create the necessary mechanical motion to operate machinery and equipment in factories.

- Enhancing Production Efficiency: By providing power to automated systems, motors help enhance production efficiency and productivity.

- Controlling Processes: Motors can adjust speed and direction of motion to control production processes more precisely.

- Ensuring Stability: Industrial motors help maintain stability in system operations, minimizing disruption and enhancing reliability.

Famous Industrial Motor Manufacturers

- Grundfos: One of the world’s leading manufacturers of industrial motors and pumping equipment, notable for providing efficient and durable solutions for many industrial sectors. Founded in Denmark in 1945, Grundfos has built a solid reputation based on excellent product quality and advanced technology. Grundfos provides many types of industrial motors, prominently featuring products such as pump motors, control motors, AC and DC motors…

- SEW-EURODRIVE: Often simply called SEW, is one of the leading manufacturers of industrial motors and drive systems. SEW specializes in providing industrial motor products including asynchronous motors, synchronous motors, servo motors, and similar motors. These are important products in drive and automation systems across many industries.

- ABB (Asea Brown Boveri): One of the leading technology groups notable for providing solutions in the field of electricity, automation, and industrial drives. ABB has built a strong reputation thanks to product quality and technological innovation. They provide a range of electric motors, from standard motors to special motors for complex industrial applications including: high-efficiency motors, explosion-proof motors, servo motors, synchronous and asynchronous motors,…

TESFA CO., LTD. is currently a reliable strategic partner chosen by Grundfos, Sew, and ABB to represent and distribute their industrial motor products in the Vietnamese market. Contact us now to get support and experience quality product lines.